Material Reliability Testing

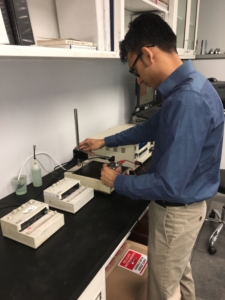

The APC Materials Reliability Testing Laboratory conducts thickness, hardness and composition testing of electroplated and anodized products. Advanced instrumentation, coupled with our highly skilled quality and technical teams offers a unique combination of skills, experience and capabilities to perform material characterization and failure-mode analysis.

STEP analysis (Simultaneous Thickness and Electrochemical Potential) is employed to determine the total electroplated deposit thickness and millivolt potential of a part.

In-house capabilities include the following techniques:

- STEP analysis (Simultaneous Thickness and Electrochemical Potential) is employed to determine coating thicknesses and the electrochemical potential between the layers of a multiplex nickel coating.

- Multilayer thickness through cross section, as well as via electrical conductivity of non-magnetic metals (e.g. copper and aluminum) is performed using a SIGMASCOPE.

- Coulometric testing is used to determine the hardness of semi-bright deposits.

- X-Ray Fluorescence non-destructive analysis is conducted to determine material composition.

- Eddy Current methodology, as well as cross sectional thickness methodology is applied towards anodized products.

The Materials Reliability Testing Laboratory is also equipped to perform tests following the ASTM and ISO standards, such as ASTM B456-11, ASTM B733-04, ASTM B571-97, ASTM E290-14, ISO 20566, ISO 2360, ISO 4516. Stress, ductility, adhesion, temperature resistance, alkaline resistance, car wash simulation and other tests are conducted daily. The lab includes micro-hardness tester to verify stable hardness of various nickel deposits.